Calipers aren’t the only part of the brake system that will need to be rebuilt occasionally. The master cylinder, which powers the entire hydraulic system, needs attention from time to time. If it has a problem, you won’t get full performance from your brakes. The most common issue is a piston with a worn primary or secondary cup, which allows hydraulic fluid to flow past the seal, resulting in low braking power or leaking at the brake lever. The master cylinder also has several tiny orifices that, if they clog, can prevent proper operation of the brakes. If you have gone through the trouble of rebuilding the calipers, you should spend the extra time to clean and inspect the master cylinder.

MO Wrenching: How To Bleed Your Brakes

MO Wrenching: How To Replace Brake Pads

MO Wrenching: Brake Caliper Rebuild

MO Wrenching: How To Install Braided Steel Brake Lines

Drain the system and disconnect the brake line. On units with a remote reservoir, remove the hose connecting the reservoir to the master cylinder and unbolt it from its mounting bracket. Remove the brake lever or pedal, and the wires leading to the brake switch. Take the master cylinder off of the clip-on or the footpeg hanger/frame for the remainder of the steps. Using a pick, carefully remove the dust cover and inspect it for cracks or punctures. If you find any, replace it. Look inside the piston bore for any signs of brake fluid leakage. If you see any, the piston needs to be replaced. Remove the circlip that holds the piston in its bore. The piston should slide out far enough for you to remove it by hand. Do not attempt to remove either the primary or secondary cups from the piston, as you will damage them. For rear-brake master cylinders, follow the same steps.

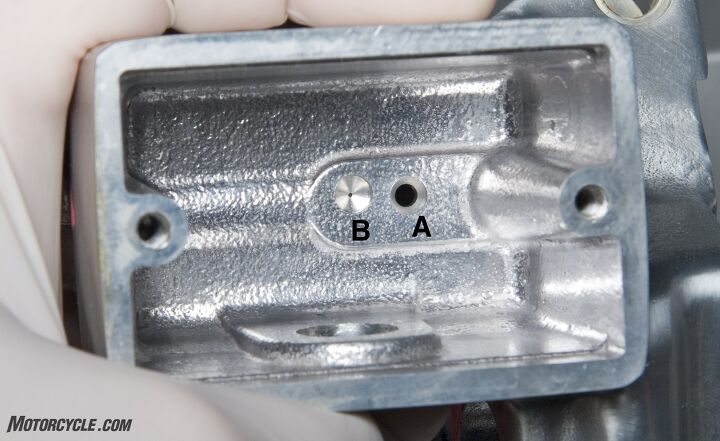

With the piston removed, give the master cylinder a thorough flush with an organic cleaner. (The rubber parts on the piston require special treatment and should only be cleaned with brake fluid or isopropyl alcohol.) Make sure all solvents are rinsed away with brake cleaner from the master cylinder internals. Blow it dry with compressed air. Closely inspect the piston bore. If you find any corrosion, rust pitting or scratches, replace the master cylinder and the piston (which may have had its cups damaged by the abrasive corrosion). Make sure the supply and relief ports between the reservoir and the piston bore are clear. A piece of grit blocking the relief port can cause your brakes to drag, reducing pad and disc life. Blow the ports clear with compressed air. If you can’t clear the port with air, carefully use a piece of safety wire, but beware, damaging the port will affect the function of your brakes and require that the master cylinder be replaced.

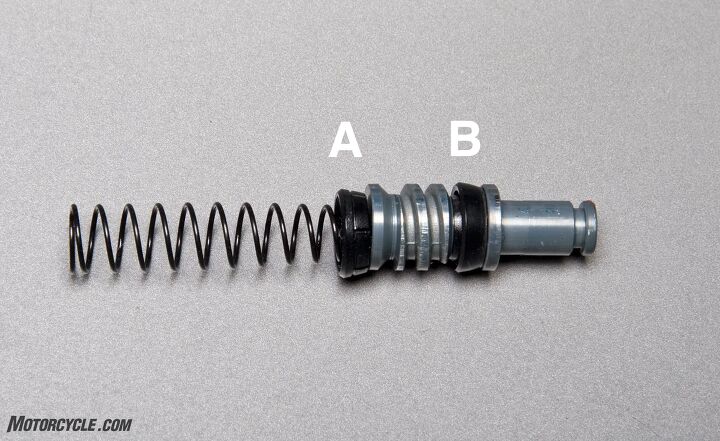

Inspect the primary (A) and secondary (B) cups for any signs of swelling or wear. The piston and spring should be free of corrosion.

A tight seal is necessary for maximum braking power. So, give the piston a once-, (or even a twice-) over. If either cup is worn, rotted or swollen, replace the entire piston assembly. If the piston has any visible rust or corrosion, replace it. Finally, check the return spring for any kinks or corrosion and replace if necessary.

Before reassembling your master cylinder, coat the interior of the piston bore with brake fluid. Coat the piston cups with fluid. Make sure the return spring has the correct orientation before inserting the piston. Press the piston in as you reinstall the circlip. Don’t forget to make sure that the dust cover is properly installed, sealing the piston from the outside environment. Remount the brake lever, and be sure to lube the pivot with grease and torque the pivot bolt’s lock nut. Bolt the master cylinder to the clip-on or frame. Attach the brake line with a fresh set of crush washers and torque the banjo bolt to spec. Reconnect the reservoir and bleed the system.

MO Wrenching: Brake Master Cylinder Rebuild appeared first on Motorcycle.com.

【Top 10 Malaysia & Singapore Most Beautiful Girls】Have you follow?